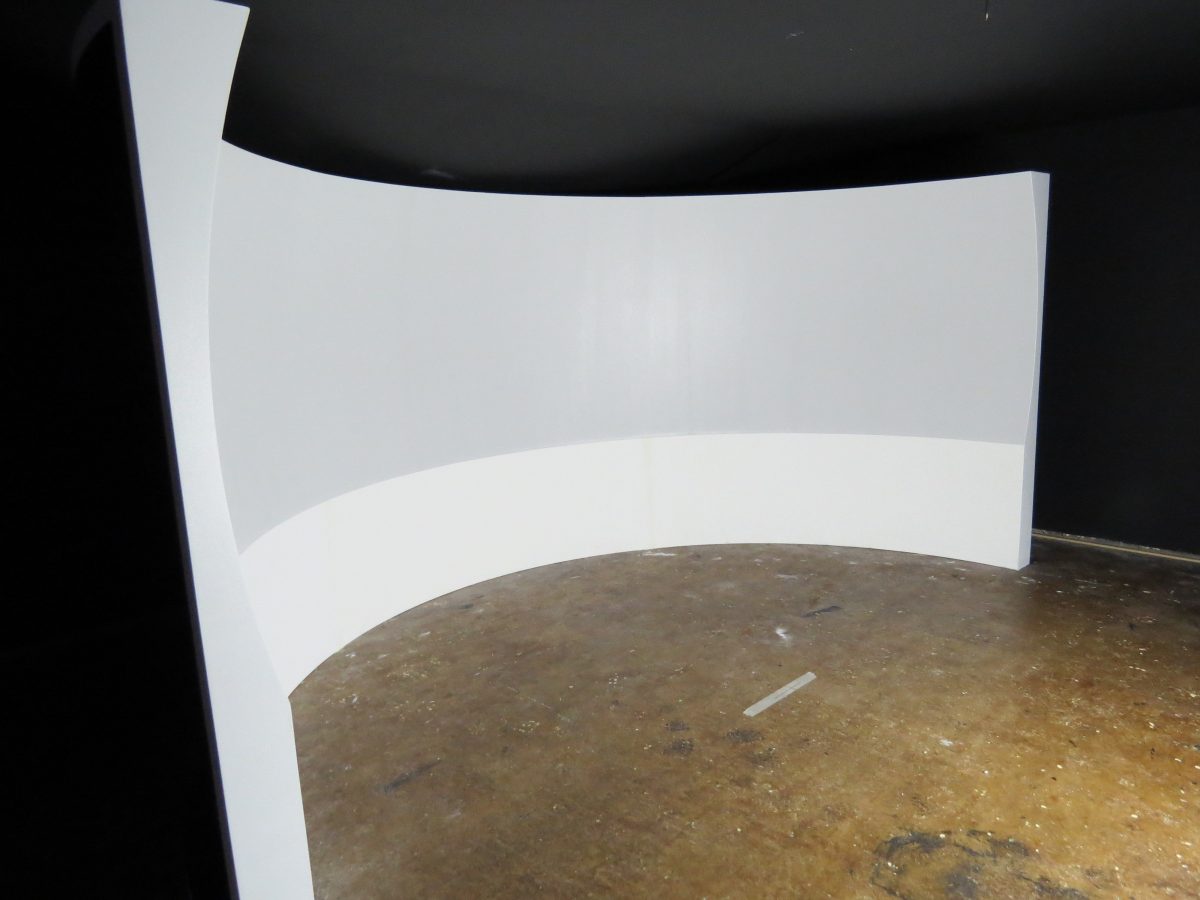

GRP Simulator Screens

Custom Mouldings are renowned for our exceptional GRP simulator screen manufacturing and installation services: we’re the ‘go to’ partner for organisations around the world. From London to Germany, Rome to Langkawi, our highly skilled team provides bespoke screens and domes, crafted to design specifications for an exciting client base.

What We Offer

GRP Simulator Screens

Our GRP simulator screen and dome solutions can be customised for:

- GRP Spherical and Cylindrical Simulator Screens

- F1 Driving Simulator Screens

- Driver training Simulator Screens

- Navy training simulator screens

- Theme Park Immersive tunnel simulator screens

- Hemispherical GRP Domes

Powerful Simulator Screens

GRP (glass-reinforced plastic) simulator screens are used in a variety of applications to create immersive experiences, such as simulations or virtual reality environments. These screens are made from a combination of glass fibres and plastic resin, which makes them strong and durable while also being lightweight.

One of the main benefits of using a GRP simulator screen is the wide field of view that it provides. The screen can be made in various sizes and shapes to fit the specific needs of the application, and it allows users to look in any direction and see the simulated environment around them. This can help to create a more immersive and realistic experience, as it allows users to feel like they are truely “inside” the simulation.

GRP simulator screens are a specialist solution that combine strength, precision and versatility, making them essential in industries where training, testing and immersive experiences are required. At Custom Mouldings we design and manufacture high quality simulator screens using glass reinforced plastic, also known as GRP. This material is perfectly suited to the task, offering durability, lightweight construction and the ability to form seamless, curved surfaces that create an accurate and engaging simulation environment.

The demand for simulator screens has grown significantly in recent years as more sectors adopt advanced training methods and virtual environments. Whether for aviation, automotive, marine, defence or entertainment, simulators require structures that are reliable, hard wearing and capable of providing a flawless visual surface. GRP has become the material of choice for this type of application because it is strong yet easy to shape into large, smooth and complex forms. At Custom Mouldings we have the expertise to deliver GRP simulator screens that meet the exact requirements of each project, ensuring precision and quality at every stage of the process.

One of the most important factors in simulator design is the accuracy and consistency of the screen surface. Even the smallest imperfections can distort visuals and reduce the effectiveness of the training or simulation experience. GRP allows us to manufacture screens with exceptional surface quality, maintaining the smoothness and stability needed for accurate projection. The lightweight nature of GRP also means that large scale screens can be created without adding excessive weight to the overall simulator structure, which is a critical consideration in many projects.

Every simulator has unique specifications, and our ability to provide bespoke solutions ensures that clients receive screens tailored to their exact needs. At Custom Mouldings we work closely with clients from the initial consultation through to installation, taking into account the dimensions, curvature and technical requirements of the simulator. Our custom manufacturing process enables us to create one off designs as well as replicate existing models with precision. The result is a product that integrates seamlessly with the simulator environment and delivers long lasting performance.

GRP simulator screens are not only practical but also highly durable. The material is resistant to wear, impact and environmental factors, meaning that screens retain their quality and functionality even after prolonged use. This durability is especially important in high intensity training environments where simulators are used frequently and reliability cannot be compromised. By investing in GRP simulator screens from Custom Mouldings, clients benefit from components that are designed to provide consistent results over the long term.

At Custom Mouldings we combine advanced moulding techniques with skilled craftsmanship to produce simulator screens of outstanding quality. We understand the critical role that accuracy and durability play in simulation and take pride in delivering products that meet the highest standards. Our experience in working with GRP across a wide range of industries means we can adapt our approach to suit any type of simulator project.

If you are looking for a trusted partner to provide GRP simulator screens, Custom Mouldings can offer the expertise and reliability you need. Our bespoke approach ensures that every screen we produce is tailored to the demands of the project, delivering a flawless surface and robust performance. Contact us today to discuss your requirements and find out how our GRP simulator screens can enhance your simulation experience.

Simulate True Experiences

GRP simulator screens are often used in military training simulations, aviation simulators, and other applications where realism and accuracy are important. They are also popular for use in observatories and planetariums, where the clear, unobstructed view provided by the screen allows for an unparalleled viewing experience of the night sky or other visual displays.

Overall, GRP simulator screens are a versatile and effective tool for creating immersive experiences and environments, and are used in a wide range of applications where realism and accuracy are important.